Top Techniques for Metal Bending in Modern Manufacturing?

In the realm of modern manufacturing, metal bending stands as a crucial process. This technique shapes materials into precise designs for various applications. John Smith, a noted expert in metal bending, emphasizes, “The right techniques can transform simple alloys into valuable components.” His insight underlines the importance of mastering bending methods for industry success.

Metal bending involves multiple techniques, each with unique challenges. From press braking to rotary bending, manufacturers must choose wisely. Different metals respond differently to bending forces. This complexity requires skilled operators to minimize defects. Often, mistakes in bending lead to material wastage. Each miscalculation prompts a re-evaluation of methods and machinery.

As technology advances, innovative machinery enhances precision in metal bending. However, human error remains a factor. New equipment can be costly, pushing teams to weigh benefits against risks. Continuous training and adaptation are vital in this evolving landscape. Metal bending is not just a method; it’s an art that demands reflection and improvement.

Overview of Metal Bending Techniques in Modern Manufacturing

Metal bending is a crucial process in manufacturing. Various techniques cater to different needs. One popular method is press brake bending. It uses a punch and die system to shape metal sheets. This technique allows for precision and repeatability. However, incorrect setup can lead to part defects. Proper alignment is often overlooked, causing costly errors.

Another widely used technique is roll bending. This method involves passing metal through a set of rollers. It is effective for creating curves and cylindrical shapes. The challenge here lies in achieving uniform thickness. Operators must monitor the material carefully during the process. Minor adjustments can make a significant difference in the final product.

Lastly, induction bending is a modern approach. It uses induction heating to soften metal sections before bending. This allows for tighter radii and complex shapes. However, the equipment can be expensive, and training is essential. If not done correctly, overheating can weaken the material. Balancing efficiency and quality remains a critical issue in all bending methods.

Top Techniques for Metal Bending in Modern Manufacturing

Common Materials Used in Metal Bending Processes

Metal bending is a crucial process in modern manufacturing. Various materials are commonly used, each with its unique properties. Steel is the most frequently chosen metal due to its strength and versatility. Aluminum, lightweight and malleable, often comes into play for parts requiring less weight. Copper is another option, known for its excellent electrical conductivity.

When selecting materials for bending, it’s vital to consider their thickness and alloy composition. For instance, thicker metals may require more force and specialized equipment to bend. Different alloys also respond differently to bending processes. Experimenting with these factors can lead to imperfections that require adjustment.

Tips: Always conduct a test bend before the final operation. This helps in understanding the material's behavior. Watch for cracks or deformation. If issues arise, reassess the bending parameters. Understanding your material minimizes mistakes and enhances quality.

Mechanical Methods of Metal Bending: Overview and Applications

Metal bending is a crucial aspect of modern manufacturing. Mechanical methods dominate this process. Techniques like press braking, roll forming, and stretch forming are commonly used. Each method serves distinct applications in industries ranging from automotive to aerospace. Reports show that the global metal bending market is projected to reach $15 billion by 2025, showcasing its significance.

Press braking is straightforward yet effective. It uses a punch and die to create desired angles. Data illustrates this method boasts a 90% efficiency rate in material usage. However, it often results in material strain, potentially compromising the metal's integrity. In contrast, roll forming continuously shapes materials. While efficient, this method has a steep setup cost. This can pose a barrier for smaller manufacturers.

Stretch forming offers unique advantages as well. It allows for complex shapes without excessive force. Yet, this technique demands precise skill. A small error can lead to significant waste. Additionally, quality control is crucial. Proper inspection protocols must be in place to avoid costly mistakes. As the market grows, manufacturers must refine their techniques. This ensures they remain competitive in an ever-evolving industry.

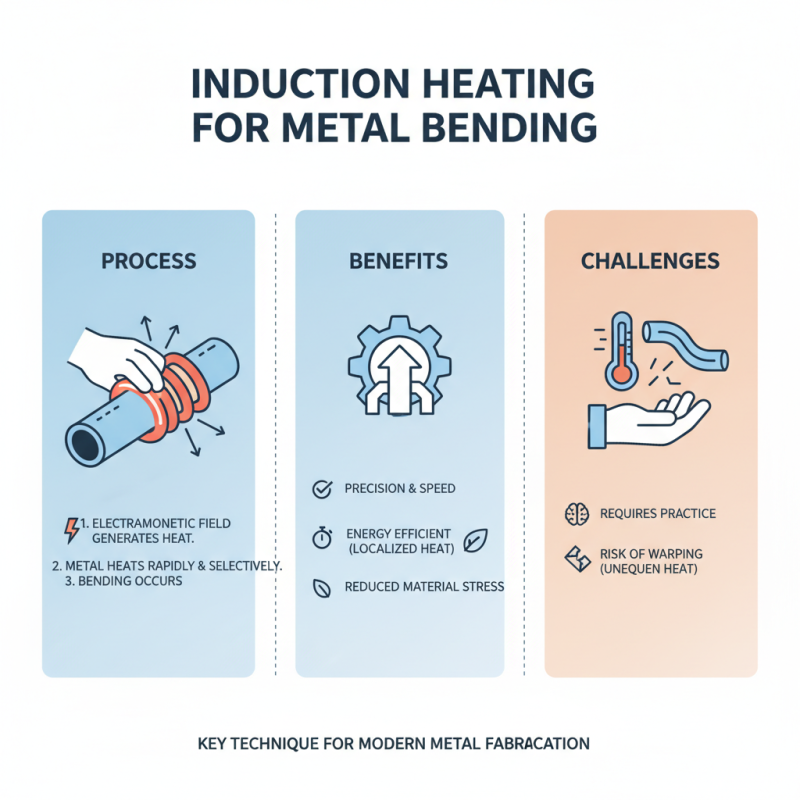

Heat-Based Techniques for Metal Bending: Induction and Gas Methods

Heat-based techniques are increasingly popular in metal bending. Induction heating stands out in this process. It uses electromagnetic fields to heat metal. This method offers precision and speed. Parts can be heated selectively. This saves energy. However, it requires practice. Operators must ensure even heating. Uneven temperatures can lead to warping.

Gas methods also play a significant role. They utilize flames to bend metal. This technique is versatile and allows for larger workpieces. It can be easier to control. Yet, it demands attention to detail. The flame must be consistent. Too much heat can weaken the material. Maintaining the right distance from the flame is crucial.

Both techniques have their pros and cons. They require different skill sets and setups. Training is necessary to master these methods. Operators often face challenges, especially with complex shapes. It’s essential to learn from these experiences. Reflecting on mistakes can lead to improvement. Experimentation might yield better results. Embracing a learning mindset is vital in modern manufacturing.

Innovations in Metal Bending Technology and Industry Trends

Innovations in metal bending technology continue to transform the manufacturing landscape. From hydraulic presses to CNC machines, the tools are becoming more precise. New software aids in designing complex curves. This helps to reduce waste and save time. Lightweight materials are gaining popularity due to their ease of bending. These advances not only enhance efficiency but also improve product quality.

Industry trends highlight a shift towards automation. Robots are now performing tasks once done manually. This approach improves speed and consistency. However, not all manufacturers have adapted quickly. There is still a reliance on outdated techniques. This can lead to inconsistencies and production delays. Manufacturers need to invest in training. Skilled workers are essential to utilize modern technologies effectively.

Sustainability is another focal point in metal bending. Eco-friendly practices are becoming a priority. Recycling metal reduces the need for raw materials. This practice supports a circular economy. Yet, implementing sustainable practices is challenging for many companies. Balancing cost with eco-friendly solutions often creates dilemmas. Industry leaders will need to address these complexities to thrive in a changing market.

Related Posts

-

Exploring Advanced Metal Welding Techniques: Boosting Efficiency and Quality in Industrial Applications

-

How to Choose the Right Industrial Sheet Metal for Your Project Needs

-

How to Choose the Best Tools for Metal Cutting in Your Workshop

-

10 Essential Metal Working Tips for Beginners to Enhance Skills

-

Exploring the Versatility of Metal Tubes: Innovative Applications You Didn't Know About

-

Top 10 Tips for Sheet Metal Bending Techniques You Need to Know